industrial Automation

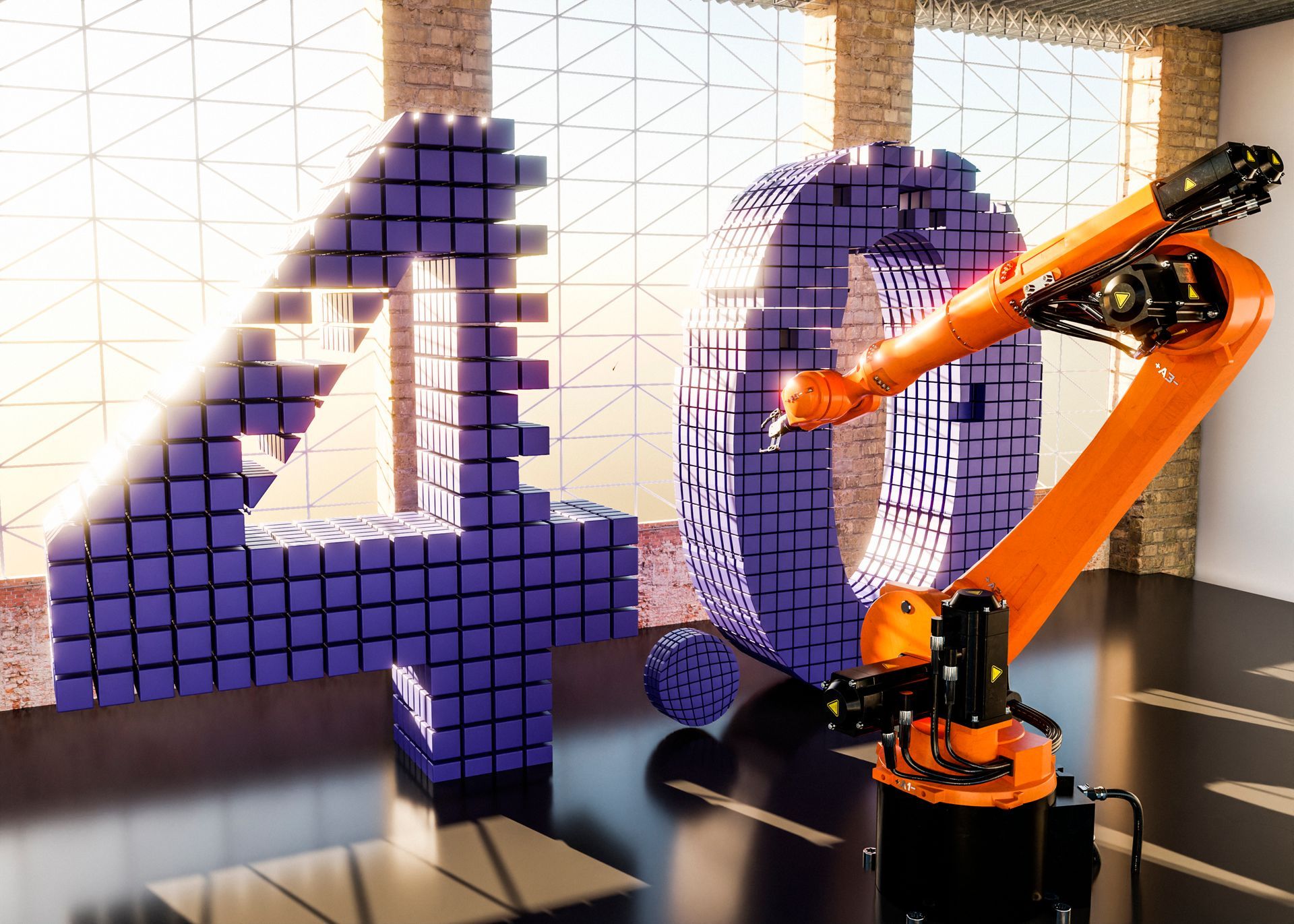

The Industrial Automation Revolution 4.0 represents the next phase of industrial evolution, characterized by the integration of advanced technologies such as artificial intelligence, machine learning, Internet of Things (IoT), big data analytics, and robotics into manufacturing and production processe

Industrial Automation

Industrial automation, in alignment with Industrial IoT (IIoT) and Industry 4.0, represents the convergence of advanced technologies to revolutionize manufacturing and industrial processes. At its core, industrial automation entails the use of automated systems, robotics, and digital technologies to streamline operations, enhance productivity, and drive efficiency in industrial settings.

How Industrial Computing Aligns with Industry 4.0 and IIoT:

By integrating Industrial IoT capabilities, industrial automation systems leverage interconnected devices, sensors, and machines to collect and exchange real-time data across the production chain. This data serves as the foundation for informed decision-making, predictive maintenance, and optimization of manufacturing processes.

Industry 4.0, on the other hand, builds upon the principles of automation and connectivity to create smart factories and digital enterprises. It encompasses the seamless integration of cyber-physical systems, cloud computing, big data analytics, and artificial intelligence to enable autonomous manufacturing, flexible production, and personalized products.

Together, industrial automation, IIoT, and Industry 4.0 drive transformative change across various industrial sectors, including manufacturing, logistics, energy, and transportation. These technologies empower organizations to:

01Improve Operational Efficiency

By automating routine tasks, optimizing workflows, and reducing manual intervention, industrial automation enhances efficiency and productivity in manufacturing operations.

02Enhance Quality and Consistency

Automated systems ensure consistent product quality by minimizing human error and variability, leading to improved product reliability and customer satisfaction.

03Enable Predictive Maintenance

Industrial IoT sensors monitor equipment performance in real-time, enabling predictive maintenance strategies that preemptively address issues before they lead to costly downtime or failures.

04Enable Agile Manufacturing

Industry 4.0 technologies enable agile manufacturing processes that can quickly adapt to changing market demands, customize products, and optimize production schedules.

05Increase Safety and Compliance

Automation reduces the risk of workplace accidents by handling hazardous tasks and enforcing safety protocols. Additionally, IIoT systems facilitate compliance with industry regulations and standards through real-time monitoring and reporting.

06Foster Innovation and Collaboration

Digital technologies foster innovation by providing access to actionable insights, enabling collaboration between humans and machines, and facilitating the development of new products and services.

WORKING TOGETHER

We work with you to come up with the very best solutions for your challenges!

01

Factory Automation

Delve into the advancements in machinery and equipment, highlighting innovations like the automated spray paint line that streamline production processes.

02

process automatin

Explore the transformative effects of automation in diverse sectors, including water treatment (RO Plants), air separation units, steel and pharmaceutical manufacturing, and wastewater treatment plants.

03

distributed control systm (dcs)

A deep dive into the interconnected systems that allow centralized data archiving and control in diverse industries.

04

oil pipeline pump station automation

Understand how technology is ensuring efficient, safe, and streamlined operations in oil transport and pumping stations.

05

package system automation

Explore how technology ensures precision, tracking, and efficiency in modern packaging processes.

06

oil wells remote monitoring

Discover that how new Communcation technologies such as LoRa and LoRaWAN can do the remote wells monitoring and Automatic shutdown.

07

baggage handeling automation

Get an insight into the seamless, error-free systems that transport luggage in modern airports.

08

Paragraph title

This is the text area for this paragraph. To change it, simply click here and start typing.

09

remote generator monitoring

Explore the cutting-edge systems that ensure efficient, synchronized, and remote power generation monitoring.

10

tunnel lighting control automation

Understand the smart systems in place ensuring optimal lighting conditions in tunnels, enhancing safety and visibility.